Photogrammetry basics: How drones create accurate 3D models

Dec 28, 2025

Updated:

Feb 4, 2026

Drone photogrammetry explained: How overlapping photos create 3D models, what determines accuracy, and why GCPs matter.

What if you could survey your entire construction site in 30 minutes instead of three days and get more accurate results?

That’s exactly what EUROVIA CZ discovered on their railway modernization project. Traditional surveying required multiple workers and consumed days of site time. With drone photogrammetry, their construction manager captures the same data in half an hour, and the €4,000 investment paid for itself within three months.

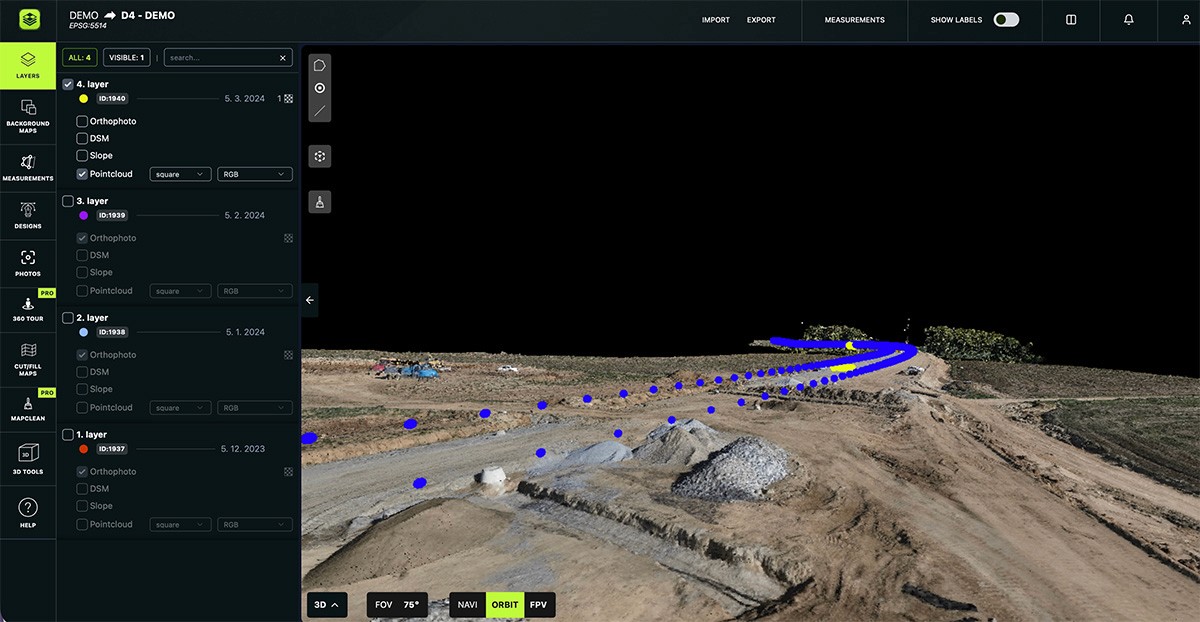

This isn’t an isolated success story. Across Europe, construction teams are discovering that using drones transforms how projects are monitored and managed. On the 32-kilometer D4 highway project, Via Salis reduced surveying time from weeks to a single day while tracking 2,127,000 m³ of excavated material with precision accurate enough for invoicing.

Teams can now overlay project designs on real terrain, calculate volumes instantly, share data across entire organizations, and make decisions in hours instead of weeks. The core principle (using overlapping photographs to create three-dimensional measurements) dates to 1851, when French inventor Aimé Laussedat first recognized the potential, according to Encyclopædia Britannica. Modern drones and computing power simply made Laussedat's vision practical for everyday construction use.

This guide explains how photogrammetry actually works: how hundreds of photos become accurate 3D models, why overlap and ground sampling distance determine your data quality, what happens during processing, and where accuracy comes from. When you grasp these basics, you can capture better data, recognize potential issues, and unlock capabilities many teams never realize are possible.

What is photogrammetry?

Photogrammetry is the process of making measurements from photographs.

In simple terms, it works like human vision. Your eyes see the same object from slightly different angles, and your brain uses those differences to understand depth. Photogrammetry software does the same thing, but with hundreds or thousands of overlapping photos.

By comparing common features in multiple images, such as edges, textures, and corners, the software can calculate the exact position of those features in 3D space.

While photogrammetry has existed for over a century, drones have made it practical for everyday use by making data capture faster and more affordable.

How to capture the right drone data

The quality of a 3D model starts with how the data is collected.

Flight patterns and overlap

Drones typically fly over a site in a grid pattern, taking photos at regular intervals. Each photo must overlap with the next so the software can recognize the same features from different angles.

Industry standards recommend:

Forward overlap: 75-80% (each photo overlaps the next by three-quarters)

Side overlap: 65-70% (each flight line overlaps its neighbor by two-thirds)

Complex terrain: 80-85% or higher

More overlap improves accuracy but increases flight time and processing requirements.

Ground Sampling Distance (GSD)

Ground Sampling Distance (GSD) describes how much ground each pixel represents in the real world.

Lower GSD = more detail

Higher GSD = less detail but faster coverage

For example:

Flying at 50 m altitude ≈ 1.3 cm per pixel

Flying at 100 m altitude ≈ 2.7 cm per pixel

For most earthworks, volume tracking, and progress monitoring, a 1–2 cm GSD provides the best balance between accuracy and efficiency.

Camera settings matter

Professional drone surveys use fixed camera settings:

Locked exposure

Fixed ISO

Consistent shutter speed and focus

Why? Because changing lighting or focus between images can confuse the software and reduce model accuracy. Consistent photos lead to cleaner, more reliable results.

How to process drone images into 3D models

Once the photos are captured, they are uploaded to processing software. This is where raw images become usable data:

Image alignment (finding camera positions)

The software first looks for matching features across all photos, such as corners of buildings, gravel patterns, or edges of roads.

By finding the same features in many images, the software calculates:

Where each photo was taken

The angle of the camera at that moment

This creates a sparse point cloud, which is an initial 3D outline of the site made up of key points.

Dense point cloud (adding detail)

Each point has:

X position (east–west)

Y position (north–south)

Z position (height)

The result is a dense point cloud that accurately represents terrain, stockpiles, buildings, and structures.

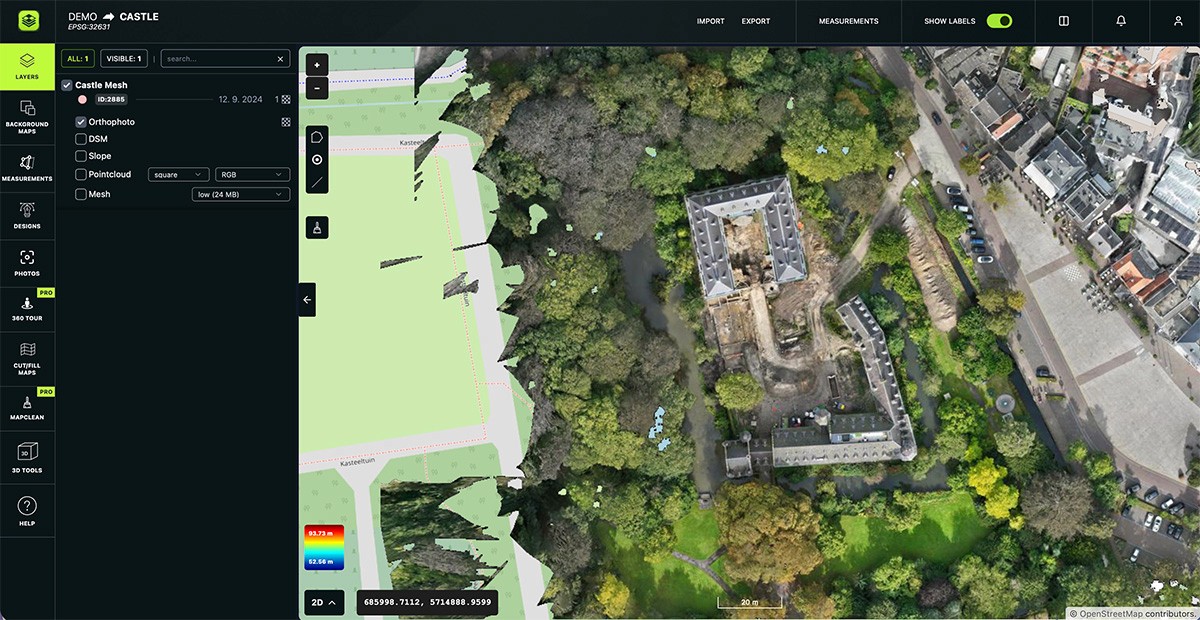

Orthomosaic (accurate 2D map)

At the same time, the software produces an orthomosaic.

An orthomosaic is a top-down aerial image that has been corrected so:

All pixels are at the same scale

There is no perspective distortion

Measurements are accurate anywhere on the image

This makes orthomosaics ideal for:

Distance and area measurements

Site comparisons over time

Plan overlays

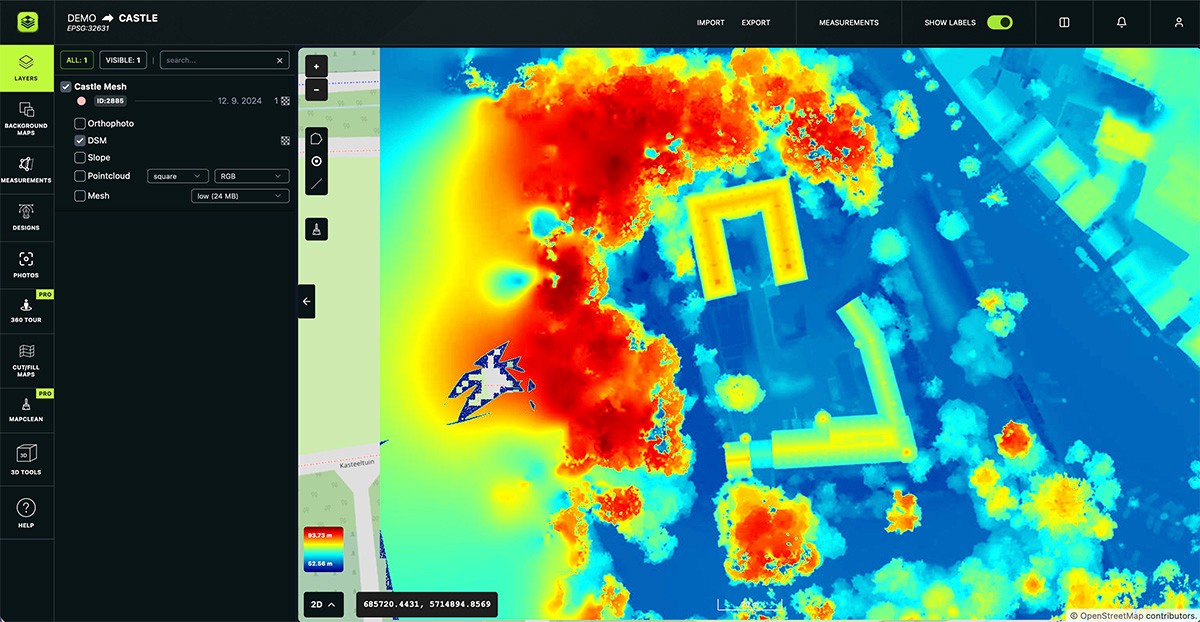

Digital Surface Model (DSM)

In addition to 3D models and orthomosaics, photogrammetry also produces a Digital Surface Model (DSM).

A DSM is a height map that represents everything the drone can see on the surface:

Ground

Stockpiles

Buildings

Tracks, roads, bridges

Machinery and other objects present during the flight

Each pixel in a DSM contains a precise elevation (Z value), not just color information.

Think of it as a simplified 3D model viewed from above, where every point has height data.

How accurate is drone photogrammetry?

Accuracy depends on how the data is captured and processed.

Ground Control Points (GCPs)

Ground Control Points (GCPs) are physical markers placed on the site with known coordinates measured by survey-grade equipment.

GCPs help “anchor” the 3D model to real-world coordinates and dramatically improve accuracy.

With properly placed GCPs, drone photogrammetry can achieve:

Horizontal accuracy: 1–3 cm

Vertical accuracy: 2–5 cm

This level of accuracy is suitable for:

Earthworks quantities

Progress verification

Contract billing support

RTK and PPK drones

Some drones use RTK (Real-Time Kinematic) or PPK (Post-Processed Kinematic) GPS systems. These improve the accuracy of each photo’s position during or after the flight.

RTK/PPK reduces the number of GCPs needed, but verification points are still recommended for critical measurements.

Common challenges (and how to avoid them)

Vegetation

Drones can only model what they can see. Dense trees or tall grass may hide the true ground surface, affecting terrain accuracy.

Solution: Combine drone data with ground surveys in vegetated areas.

Reflective surfaces

Water, glass, and shiny metal reflect light differently from different angles, which can confuse the software.

Solution: Avoid flying over reflective surfaces when possible or expect localized inaccuracies.

Shadows and lighting

Strong shadows can reduce image matching and create gaps in the model.

Solution: Fly around midday or on overcast days for even lighting.

Moving objects

Vehicles, machinery, and people can appear distorted or duplicated in the final model.

Solution: Fly during breaks, shift changes, or low-activity periods.

Turning models into decisions

Once processed, drone data becomes a practical decision-making tool with:

Cut/fill and stockpile volumes suitable for reporting and billing

Progress tracking by comparing surveys over time

As-built documentation for claims and compliance

Simple measurements accessible to the entire team

Clear visualizations that non-technical stakeholders understand instantly

By combining accurate 2D orthomosaics with interactive 3D models, teams get both precision and context.

Conclusion

Drone photogrammetry has moved from a niche surveying method to an everyday construction tool. When done correctly, it delivers accurate, repeatable, and defensible data that supports better decisions across the project lifecycle.

Understanding the basics (how photos become models and why overlap and accuracy matter) helps you use drone data with confidence.

The quality of your drone data directly affects the quality of your decisions. That’s why leading construction companies rely on AVAG not just for speed but for data they can trust when it matters most.

See what your drone data can really do

Join more than 1,000 satisfied users. Just upload your files and see results.

No credit card required

About the author

Miroslav Staubr

CEO at AVAG Pro

Miroslav Staubr is the CEO and co-owner of AirView s.r.o. and the product lead behind AVAG, a cloud platform used across construction and surveying for processing drone, LiDAR, and 3D geospatial data. As a certified drone pilot with the highest permit for aerial mapping, he brings hands-on experience working with UAVs (Unmanned Aerial Vehicles), commonly known as drones, to capture precise data for photogrammetry, terrain analysis, and earthwork volume calculations.

Subscribe and do not miss latest posts

Explore more articles

How do you measure earthworks accurately on large projects?

Jan 20, 2026

Get answers to common earthwork measurement FAQs: drone accuracy, linear project challenges, and more.

Read more

Best drone data platforms for 2026

Feb 2, 2026

Which drone data platforms stand out as the most relevant options in 2026?

Read more